Composites density measurement void measurement carbon epoxy image analysis astm d792 voids porosity astm d1505 20.

Carbon epoxy laminate density.

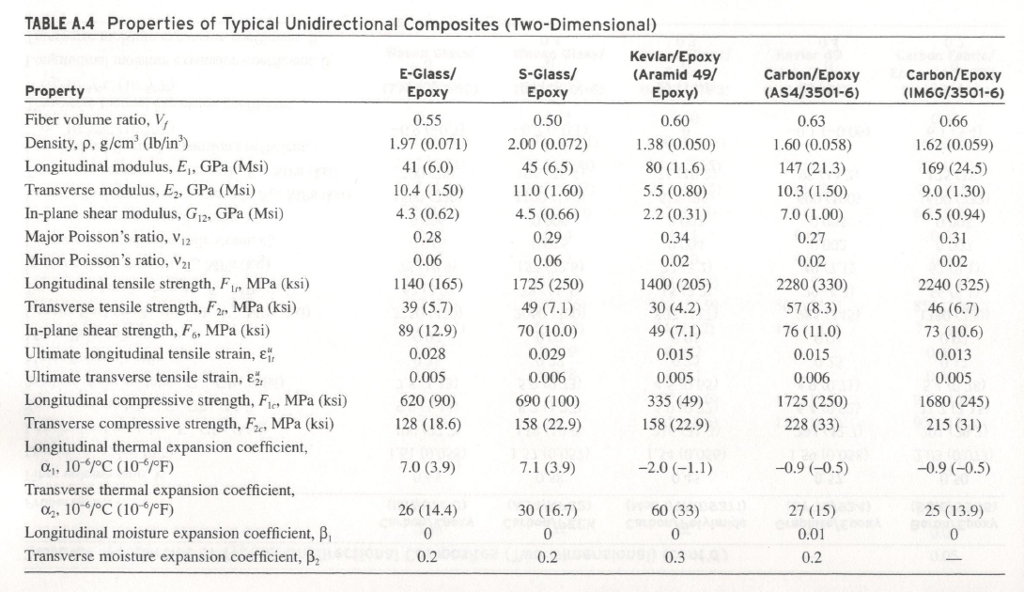

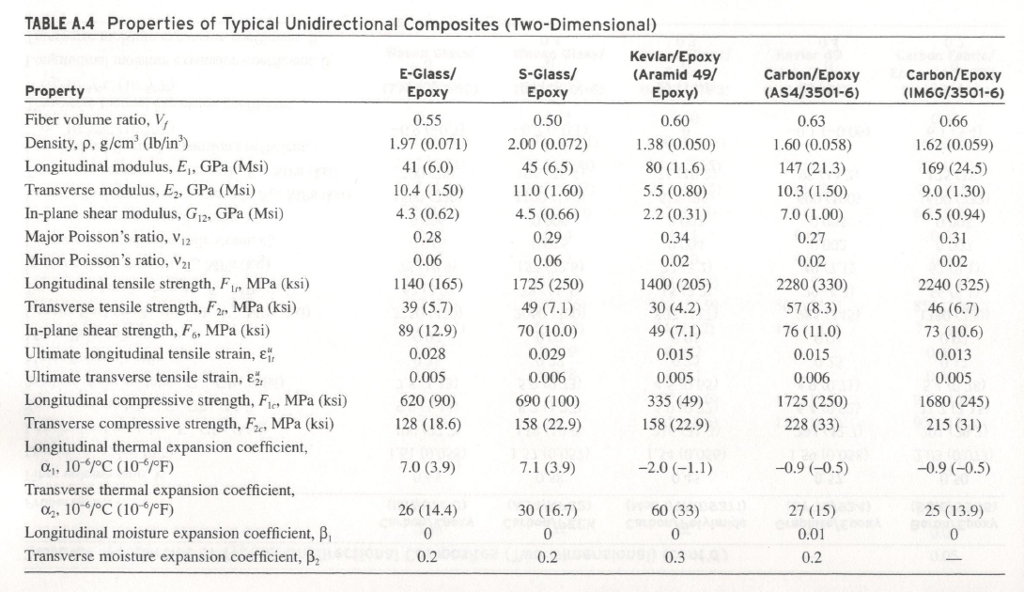

From the mechanical properties of the composite listed in table 16 2 and the shear lag model the axial modulus of as4 3501 6 carbon epoxy cross ply laminate 0 90 2 s was calculated as a function of matrix crack density from equation 16 24 and compared with the experimental data as well as the results without the effects of residual thermal.

Volume fraction of fibres 55 60.

Best tensile strength flexural modulus heat distortion temperature and linear expansion compared with other epoxy laminates.

The angle changes of the manufactured specimens were measured at room temperature 25oc by stamping the l section on a reference paper of right angle.

Properties carbon epoxy composite rod.

Investigate the spring forward behavior of carbon epoxy composite laminate structures.

A small sample of aerospace grade carbon fibre epoxy laminate in materials science a composite laminate is an assembly of layers of fibrous composite materials which can be joined to provide required engineering properties including in plane stiffness bending stiffness strength and coefficient of thermal expansion.

Thermal expansion coefficient longitudinal.

Carbon fibres exhibit generally superior performance in tensile compressive and flexural properties as well as fatigue resistance.

Also excellent interlaminar and in plane shear strengths.

Properties carbon epoxy composite tube.

Abstract camd n revwe side if neceza and idemify by block mb gr see reverse side form edition of 1 nov 65 is obsolete dd ijan 731473 unclassified security classification of this page when daa entered.